Interior elements are subject to cleaning agents, alcohol, food acids, scratches, UV exposure, children's toys, pets, and more. To ensure the highest protection against these influences you want to offer a topcoat to your customers that can rely and offer resistance against this.

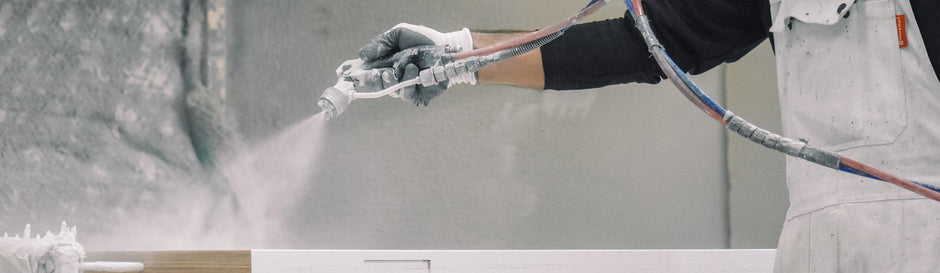

Production tests for transparent and opaque topcoats

The Anker Stuy interior topcoat is designed to offer the highest protection possible, and in combination with our Aplexol Aqua Hardener we can also offer resistance against moisture in bathrooms and kitchens.

One of the product tests we do for our transparent and opaque topcoats is the drop test. Various acids, alcohols, and cleaning agents are loaded on the surface for 48 hours. After that time, these droplets should not leave any marks.

Another test that we do is the abrasion test. This ensures scratch resistance and will make sure that the surface is hard enough to resist impacts from falling objects such as keys being thrown on a table. We show this test on picture below.

Our interior topcoats and primers also comply with the DIN EN 71-3, child toy safety. This is a test with 3 specified requirements and test methods for the migration of aluminium, antimony, arsenic, barium, boron, cadmium, Chromium (III), Chromium (VI), cobalt, copper, lead, manganese, mercury, nickel, selenium, strontium, tin, organic tin, and zinc from toy materials and from parts of toys. Therefore, our interior topcoats can also be applied on baby room furniture and toys.

To create even more scratch resistance and moisture resistance for the use in public restaurants or professional kitchens for instance, we recommend adding the Aplexol Aqua Hardener. This will ensure good isolation properties and scratch resistance for places with a lot of traffic.