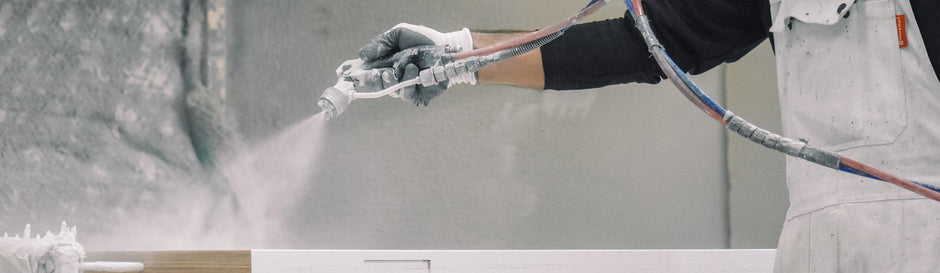

Drying Techniques for Water-Based Wood Joinery Coatings in Industrial Settings

Drying water-based wood joinery coatings in an industrial setting demands a delicate balance of time, temperature, and technique to achieve optimal results. From the application of coatings to their final curing, each step in the drying process plays a crucial role in ensuring the quality and durability of the finish. In this blog, we will explore key aspects of drying water-based wood joinery coatings, including drying tunnels, flash-off periods, time between spraying coats, handling times, and fully curing, providing insights into best practices for industrial operations.

Understanding Water-Based Wood Joinery Coatings: Water-based wood joinery coatings offer numerous advantages, including environmental friendliness, low VOC emissions, and ease of cleanup. These coatings provide excellent adhesion and protection while highlighting the natural beauty of wood surfaces. However, their drying process requires careful attention to a range of factors to achieve the desired finish quality.

Drying Techniques in Industrial Settings:

Flash-Off Periods:

- Flash-off periods refer to the critical interval between coating application and entering the drying tunnel.

- During this period, water evaporation occurs, allowing the coating to level and release trapped air bubbles.

- The flash-off is defined by little to no air movement and an ambient temperature. If force drying is taking place, an initial flash-off is essential.

- The duration of the flash-off period depends on factors such as coating viscosity, ambient temperature, and humidity levels.

- Proper flash-off periods help prevent defects like orange peel and ensure a smooth, uniform finish.

Drying Tunnels or Drying Spaces:

- Drying tunnels are essential equipment in industrial wood coating operations, providing controlled conditions for the drying process.

- These tunnels typically feature conveyors that transport coated wood pieces through a series of heated chambers, facilitating uniform drying.

- Adjustable temperature and airflow settings allow operators to tailor drying conditions to the specific requirements of the coating and substrate.

- Although purpose-built tunnels are desirable, simply having an area with airflow and a controlled temperature is sufficient. Areas with controlled humidity and temperature ensure dependable drying and curing times between coats, maintaining time efficiency and finish quality.

Time Between Spraying Coats:

- After applying the initial coat of water-based coating, allowing sufficient drying time between coats is essential.

- The recommended time between coats varies depending on factors such as coating thickness, ambient conditions, and substrate absorption.

- Typically, a period of up to 4 hours is sufficient before applying subsequent coatings.

- Adhering to proper drying times between coats promotes adhesion, minimizes the risk of sagging or runs, and enhances finish durability.

Handling Times:

- Once the final coat is applied, allowing adequate drying and curing time before handling or packaging is crucial.

- Handling times vary depending on factors such as coating type, thickness, and environmental conditions.

- While water-based coatings may dry to the touch quickly, full curing and hardness may take several hours to days, depending on the formulation.

- Premature handling can lead to surface defects or marring of the finish, compromising the overall quality of the coated wood joinery.

Fully Curing:

- Achieving full curing is essential for maximizing the performance and durability of water-based wood joinery coatings.

- Full curing refers to the complete cross-linking and polymerization of the coating film, resulting in optimal hardness, chemical resistance, and adhesion.

- Depending on the specific coating formulation and ambient conditions, full curing may take anywhere from 24 hours to several days.

- Providing adequate curing time allows the coating to reach its maximum performance properties, ensuring long-lasting protection and aesthetics.

To help with the drying process, we believe that certain equipment is essential for any joinery workshop. Although in the dry ambient months this equipment may not seem necessary, there will come a time when the shop is a little too hot, cold, wet, or dry for hassle-free spraying. With a small investment, consistent spray quality can easily be assured.

Timber Moisture Gauges:

- Pin-type moisture meters or non-invasive meters are commonly used to measure the moisture content of wood substrates.

- Regular moisture testing ensures that the wood substrate is within the optimal moisture range for coating application, preventing issues like adhesion failure or cracking.

We recommend the following options:

Wagner Meters Orion® 950 Pinless Moisture Meter

This meter distinguishes itself as the premier choice for multiple reasons, rendering it an essential asset for individuals engaged in woodworking. Its foremost attribute is its remarkable accuracy, featuring a non-invasive pinless sensor coupled with IntelliSense technology for precise moisture readings without compromising the integrity of the wood.

Mini-Ligno DX/C Moisture Meter

This meter is ideal for dealing with diverse wood types and offers a broad measurement spectrum for both dry and wet lumber. Its LED display ensures readability in dim settings, and its reliability is backed by a lifetime warranty.

Humidity and Temperature Gauges:

- Digital hygrometers and thermometers are essential for monitoring ambient conditions during coating application.

- Maintaining consistent humidity and temperature levels within the recommended range helps achieve optimal coating performance and drying characteristics.

Heating and Infrared Systems:

Infrared heaters or drying systems can be employed to control ambient temperature and accelerate drying times in colder environments. Proper heating ensures uniform drying of water-based coatings, reducing the risk of defects like orange peel or surface imperfections.

Brands like