Choosing the Perfect Finish: A Guide to Translucent Coatings for Exterior Joinery

Translucent coatings for exterior joinery can sometimes lead to a bit of a debate. However, what is obvious is that choosing the correct coating is essential for enhancing both aesthetics and durability of wood. Exterior joinery comprises different elements requiring specific protection against environmental factors. This blog explains the difference between 'dimensionally stable joinery', made from woods like sapele or engineered products like Accoya, and 'non-dimensionally stable joinery', often made from pine or fir. Each has its typical usage outside and this has an impact on which coating type to use.

It's also important to understand the difference between film-forming and non-film-forming coatings. Film-forming coatings, like paints, create a protective surface layer making paint suitable for windows and doors, however, when used for cladding this type of paint can crack or peel when exposed to excess moisture. On the other hand, non-film-forming coatings, such as oils and stains, penetrate the wood, providing internal protection and allowing the wood to breathe and move naturally, but this is certainly not what you want with windows and doors as they will jam and warp.

The final thing to consider is the pigment load in coatings; this is crucial for both visual appeal and functional protection. Pigments enhance wood colour and protect against UV radiation, preventing fading and damage. You should never use a completely translucent finish; without pigments in the coating, the system will fail very quickly – despite having UV blockers. This blog will explore these factors to help you choose the right coatings for your exterior joinery, ensuring lasting beauty and durability.

Dimensional Stability in Joinery: Understanding the Differences

When it comes to wood joinery, the terms "dimensionally stable" and "non-dimensionally stable" refer to how much a piece of wood changes in size and shape due to environmental factors such as moisture and temperature. Understanding the differences between these types of joinery is crucial for selecting the right materials and construction methods for your woodworking projects.

Dimensionally Stable Joinery

Dimensionally stable joinery refers to wood and wood products that maintain their dimensions relatively well under varying environmental conditions. This stability is a result of several factors:

- Material Selection: Certain types of wood, such as cedar, mahogany, and teak, are naturally more stable due to their lower tendency to absorb and lose moisture. Engineered wood products like Accoya and Tricoya are also designed to be more dimensionally stable.

- Kiln Drying: Wood that has been properly kiln-dried has a reduced moisture content, which minimizes expansion and contraction.

- Construction Techniques: Joinery techniques that accommodate wood movement, such as floating panels in frames and the use of mechanical fasteners that allow slight movement, contribute to dimensional stability.

Applications and Benefits

- Precision Fit: Dimensionally stable wood is crucial for applications where precise fits are necessary, such as in windows and doors.

- Durability: Stability enhances the longevity of the joinery, as the wood is less likely to warp, crack, or split over time.

- Consistency: Provides a consistent appearance and performance, which is vital for high-quality woodworking projects.

Typical uses

Windows, doors, and facades

Most suitable paint

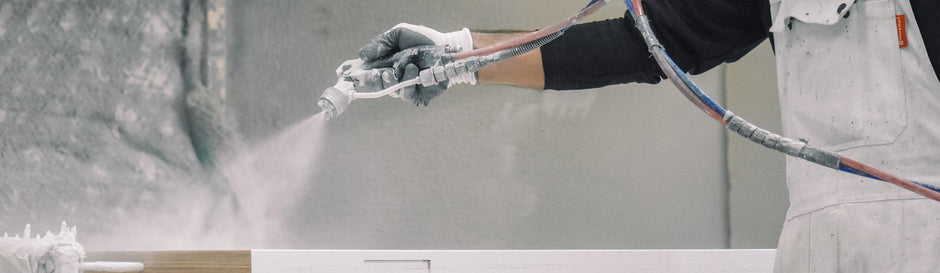

The Hydrolux system is perfect for windows and doors because it provides excellent durability and weather resistance, ensuring long-lasting protection against the elements. Additionally, its quick-drying properties and low VOC content make it an environmentally friendly choice that facilitates efficient application and reduces downtime.

Non-Dimensionally Stable Joinery

Non-dimensionally stable joinery refers to wood that is more susceptible to changes in size and shape due to environmental factors. This instability can be influenced by several aspects:

- Wood Species: Some woods, like pine and fir, are more prone to absorbing and releasing moisture, leading to greater dimensional changes.

- Improper Drying: Wood that has not been adequately dried or has been exposed to varying moisture levels after drying can be highly unstable.

- Poor Construction Techniques: Joinery methods that do not account for wood movement, such as rigid gluing of large panels, can exacerbate instability.

Challenges and Considerations

- Warping and Cracking: Non-dimensionally stable wood is more likely to warp, crack, or split, especially when exposed to changes in humidity and temperature.

- Fit and Finish Issues: Components may not fit together as precisely, leading to gaps or misalignments over time.

- Maintenance: Requires more frequent maintenance and adjustments to address the effects of wood movement.

Typical uses

Cladding, garden furniture, benches, gates, etc. would all be examples of non-dimensionally stable joinery. Water will ingress into the timber from all sides and cause the wood to move. This is inevitable and inherent in the design. As a paint manufacturer, when you cannot prevent the water from entering the timber, designing products that enable the water to escape quickly becomes important.

Most suitable paint

Ankolux Aqua system is ideal for cladding, benches, and gates because it offers superior UV resistance and weatherproofing, ensuring these outdoor surfaces remain protected and visually appealing over time. Additionally, its environmentally friendly, water-based formulation provides excellent adhesion and durability, making it a sustainable and reliable choice for various exterior applications.