The Dutch window performance

The Dutch joinery industry is characterized by being innovative, but also because the market regulates itself. Requirements have been drawn up from the industry and joinery and wood federations such as the Dutch Association of joinery Manufacturers, but also SHR (Foundation Wood Research) makes sure to meet certain quality requirements. These quality standards have been further developed under KOMO certification. These developments are still going on and every year products become even better, but also more sustainable.

For over 20 years SHR has been involved in the implementation of water based industrial paint systems for joinery applications. The main focus on the performance requirements specified for the Dutch construction practice helped to develop the KOMO certification process of these paint systems. KOMO certification implies annual product confirmation tests that resulted in an interesting dataset of useful information.

Anker Stuy is market leader as paint supplier to the Dutch joinery industry and therefore all our products comply with this KOMO certification and yearly auditing by SHR.

When SHR was founded 25 years ago, paint or coatings were no big theme in joinery manufacturing. Use of solvent based wood primers was common and trusted in standard practice of construction. Including all repairs needed on windows, window frames and doors due to damages that happened in the building process.

In those days the standard operation in the building process was to position the window frames freely exposed in the field directly after the foundations were laid.

In the late 80’s, early 90’s the ministry of social affairs and employment initiated a program to reduce the use of volatile organic solvents (VOC) to less than half of the amounts used in 1985 over a 10 year time frame. From 1995 on there was more pressure from government and society (unions) to speed up the transition in the joinery industry.

At SHR in 1994 the first coatings dedicated project manager started a research project on water based coatings’ interactions with wood; wettability, penetration, adhesion, water- and vapour permeability. All related to the comparison of the new water based coatings and solvent based coatings that were supposed to be replaced.

Based on the experiences with the water based primer systems combined with the stresses released in the building process in 1995 an SKH-publication 95-01 ‘Basis of assessment for opaque primer systems for timber’ (later changed in SKH-publication 99-02 in 1999) was released where performance criteria were defined based on the common practice at that time.

Key were the so called quick scan conditions for application and drying of the water based primer system. ‘Minimum Quick-Scan conditions’ mean: the most unfavourable conditions being allowed according to SKH-Publication 98-04 “Conditions for the finishing of joinery with water-borne paints in the joinery industry”. Thus the lowest possible temperature, the highest possible relative humidity, the lowest possible air velocity and the shortest possible drying time.

Performance criteria were formulated for a minimum dry film thickness of 80 micrometre for opaque primer systems. In the years 2000 till 2005 further studies were done such as water vapour permeability in relation to dimensional stability of the joinery elements and pigmentation on the performance of the primer systems. Methods for evaluation of the water permeability and adhesion of the primer systems after quick scan conditions were further improved.

In 2005 this resulted in the first national assessment directive for film forming coatings for application on timber (Assessment Directive 0814). Based on this document SKH started from January 1st 2006 onwards to issue KOMO product certificates on industrial primer systems for the joinery industry.

Annual testing of the coating system includes a full run of water permeability after minimal drying

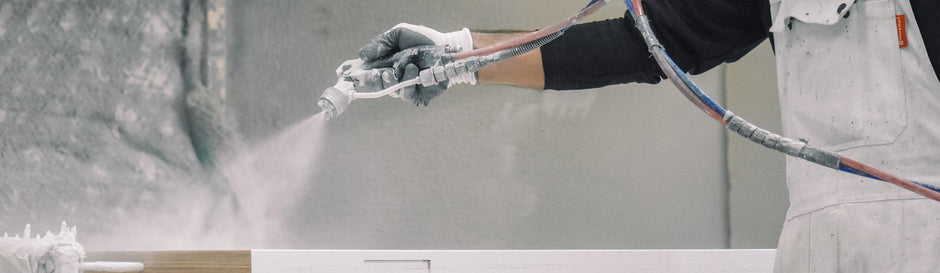

The coating system is applied by Airless/air mix spraying on 5 Norway spruce panels. The film build up is controlled by weighing the amount of applied paint for each panel per layer. The coating system is dried according to ‘Quick Scan conditions’ as indicated by the manufacturer.

The paint system is tested in the colours RAL 1013 and RAL 7026. After drying the panels are weighed, placed in fresh demineralised water for 72 hours and weighed again. Then the water uptake and (directly) adhesion are determined. Finally the panels are evaluated according to ISO 4628-4, -5 and –2 (degree of cracking, flaking and blistering).

Adhesion

Adhesion is tested after 72 hours of floating on water, directly after weighing and on a clean (dried with a tissue) surface. According to SKH Publication 05-01 four cuts are made in the paint system with the following pattern: The distances between the cuts is about 7 - 10 mm and the sharp angle between the cuts is about 30°. An adhesive tape (Scotch SC800) is placed over the cuts, pressed firmly and pulled off after one minute in an angle of 180° in a controlled movement taking about 1 second.

Water permeability after complete drying

The coating system is applied by Airless/air mix spraying on 5 Norway spruce panels. The film build up is controlled by weighing the amount of applied paint for each panel per layer. The coating system is dried according to ‘Quick Scan conditions’ as indicated by manufacturer and additionally dried for 7 days at 20°C and 65% RH.

After drying the panels are placed in fresh demineralised water for 72 hours. After weighing the panels are conditioned at 20°C and 65% RH until a constant mass is obtained (typically four weeks). Then the panels are placed again in fresh demineralised water for 72 hours, after which the water uptake is determined for the second time. Finally the adhesion and degree of blistering and cracking is determined.

Granting of the KOMO® PRODUCT CERTIFICATE

The results of the assessment audit shall be recorded in a file by the certificate body. The dossier must meet the following requirements:

- Completeness; the file gives a ruling on all the requirements of the directive;

- Traceability; the findings on which statements are based must be recorded in a traceable manner.

The decision on the granting of a KOMO® Product Certificate must be taken by a qualified decision-maker who has not himself been involved in the assessment investigation. Based on the assessment, the decision maker decides whether the KOMO® Product Certificate can be granted or whether additional data and/or assessments are required before the KOMO® Product Certificate can be granted. The decision must be recorded in a traceable manner.

EXTERNAL CONFORMITY ASSESSMENT

After the KOMO®Product Certificate has been issued, the certificate body shall carry out checks as described in chapter 9 of this Assessment Directive.

In a nutshell: these are the KOMO standards

PROPERTIES AFTER CRITICAL DRYING

The properties after critical drying are determined according to §5.1 and § 5.2, are:

| Method |

Requirement |

||

|

Water uptake |

SKH-Publ. 08-02 |

≤ 250 g/m2 |

|

|

Adhesion after water uptake |

SKH-Publ. 05-01 |

maximum class 1 |

|

PROPERTIES AFTER COMPLETE DRYING

The properties after complete drying are determined according to §5.1 and § 5.2, are:

| Method |

Requirement |

||

|

Water uptake |

SKH-Publ. 08-02 |

≤ 150 g/m2 |

|

|

Adhesion after water uptake |

SKH-Publ. 05-01 |

maximum class 1 |

|

WATER UPTAKE AND FREEZE STABILITY

After six cycles of alternating water uptake and freezing according to §5.3 the following properties are determined:

|

Method |

Requirement |

||

|

Adhesion |

SKH-Publ. 05-01 |

Maximum class 1 |

|

|

Blistering |

NEN-EN-ISO 4628-2 |

Not permitted |

|

|

Cracking |

NEN-EN-ISO 4628-4 |

Maximum class 1S1 |

|

|

Peeling |

NEN-EN-ISO 4628-5 |

Not permitted |

|

ACCELERATED WEATHERING

Accelerated weathering topcoat systems

Pending the natural outdoor durability results from § 4.5.2, the outdoor durability can be determined by accelerated weathering.

After 2016 hours (1512 hours for transparent systems) of accelerated weathering, in accordance with § 5.4, the following properties are determined:

|

Method |

Requirement covering |

Requirement transparent |

|||

|

Adhesion |

SKH-Publ. 05-01 |

Maximum class 1 |

Maximum class 1 |

||

|

Blistering |

EN-ISO 4628-2 |

Not permitted |

Not permitted |

||

|

Cracking |

EN-ISO 4628-4 |

Maximum class 3S1, 2S2, 2S3 |

Maximum class 1S1 |

||

|

Flacking |

EN-ISO 4628-5 |

Not permitted |

Not permitted |

||

|

Chalking* |

EN-ISO 4628-6 |

Maximum class 2 |

- |

||

|

Gloss |

NEN-ISO 2813 |

No requirement, just measurement at the start and end of the fast processing. |

|||

|

Colour* |

NEN-EN-ISO 11664-4 |

No requirement, only measurement at the start and after 2016 hours |

- |

||

|

Discolouration** (greying/blueing) |

SKH-Publ. 17-03 |

- |

Not permitted |

||

OUTDOOR DURABILITY TOPCOAT SYSTEM

After 60 months (for a transparent system after 36 months) of outside durability, in accordance with § 5.5, the following properties are determined:

|

Requirement covering |

Requirement transparent |

||||

|

Adhesion |

SKH-Publ. 05-01 |

Maximum class 1 |

Maximum class 1 |

||

|

Blistering |

EN-ISO 4628-2 |

Not permitted |

Not permitted |

||

|

Cracking |

EN-ISO 4628-4 |

Maximum class 3S1, 2S2, 2S3 |

Not permitted or maximum class 1S1 |

||

|

Peeling |

EN-ISO 4628-5 |

Not permitted |

Not permitted |

||

|

Chalking* |

EN-ISO 4628-6 |

Maximum class 2 |

- |

||

|

Gloss flow rate |

NEN-ISO 2813 |

No requirement, only measurement at the start, every 12 months and at the end of the outside exposure. |

|||

|

Colour retention* |

NEN-EN-ISO 11664-4 |

No requirement, just measurement at the start, every 12 months and end of outside exposure |

- |

||