Specifications of oak wood

There are many different species of oak, but the most common species used for woodworking and construction are red oak and white oak.

Red oak is known for its reddish-brown color and distinctive open grain pattern. It is a fairly hard wood, with a Janka hardness rating of 1290. It is also relatively inexpensive and widely available, making it a popular choice for furniture, cabinetry, and flooring.

White oak (see image on top), on the other hand, has a light to medium brown color and a closed grain pattern that does not have the visible pores of red oak. It is even harder than red oak, with a Janka hardness rating of 1360, and is known for its resistance to rot and decay. It is a preferred choice for exterior use, flooring, and wine barrels.

Oak wood is a durable and strong wood that is well-suited for interior joinery, but it can be more difficult to use for exterior joinery for a few reasons:

- Oak is a dense hardwood, which makes it more difficult to work with than some other types of wood. It can be challenging to cut, shape, and join due to its hardness.

- Oak is not naturally resistant to rot and decay, which is important when used in exterior joinery. While white oak is more resistant than red oak, it still needs to be treated with preservatives or sealers to protect it from the elements.

- Oak is also a hygroscopic wood, which means it absorbs and releases moisture. This can cause the wood to expand and contract with changes in humidity and temperature, which can lead to cracking and warping over time.

- Oak wood is also prone to checking, which are small cracks that develop on the surface of the wood as it dries. These checks can make the wood less stable, especially in an exterior environment.

- Oak wood, especially red oak is also prone to cupping, which occurs when the wood's surface becomes concave, and the edges become convex.

Despite these challenges, oak wood can be used for exterior joinery with proper treatment, preservation, and maintenance. It's important to use appropriate sealers and preservatives and to use appropriate techniques when working with oak to minimize checking, cupping and other issues.

Maintenance of oak joinery

Maintaining exterior oak joinery requires a bit more attention than interior joinery to protect it from the elements. Here are a few tips for maintaining exterior oak joinery:

- Regularly inspect and maintain: Check the joinery regularly for signs of damage or wear, such as rot, cracks, or warping. Address any issues as soon as they are noticed to prevent further damage. Gaps should be sealed with Hydrolux V-Joint Sealer and end grain should be maintained with Hydrolux End Grain Sealer White and for translucent finishes Hydrolux End Grain Sealer Clear.

- Keep it clean: Clean the joinery regularly to remove dirt, dust, and debris, and to keep it looking its best.

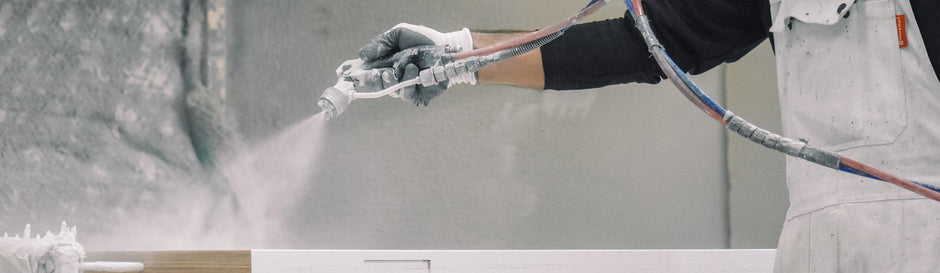

- Paint: Apply a coat of paint to the oak joinery to protect it from the elements and to enhance its appearance. We recommend for translucent finish 16-0221 Woodcoat TP which can be brushed. This is a waterborne translucent one pot system which is available in many translucent colours.

- Take care of the hardware: Make sure that the hardware used in the joinery is in good working order, and replace any hardware that is showing signs of wear or rust.

By following these tips, you can help ensure that your exterior oak joinery will last for many years and continue to look great.

Black spots on oak

Black spots on OAK is a result of moisture ingress in open joints and gaps or where the oak surface is disrupted by UV-Lights or other human damages. This could be the result of not doing any maintenance or proper maintenance. The blackening is not rot, and does not affect the structural integrity of the timber.

Sanding the timber back on these spots is the quickest solution. After sanding the surfacer back make sure you apply the right paint system for protection against UV and moisture.

We recommend following products:

Translucent: 16-0221 Woodcoat TP

Opaque: Hydrotop

Chemical solution for removal of discolouration

There are products on the market that contain an oxalic acid, which are capable to reduce discolouration in oak. However, this will never give a 100% satisfied solution and may leave white spots.