Tannin bleed can be problematic if not dealt with properly. A fresh paint job can result in yellow staining in seconds without the correct protection or slowly appear weeks later. In either case, correcting the ruined job results is nothing less than wasted labour and materials as you attempt to rectify the product, which can be very costly. With the correct precautions and preparation however, this can easily be avoided.

What is tannin bleed?

Tannic acid, or tannins, are natural constituents (often referred to as extractives) present in certain timbers that will bleed through coatings if not properly isolated. The direction and extent of tannin bleed is dependent on grain orientation and is linked to the cell structure of the timber. The timber cell structure can be likened to millions of plastic straws bundled tightly together - if a lot of water travels down the timber section it can actually ‘flush’ out the tannins in the wood causing the surrounding surfaces to become stained.

The first thing you need to understand is that moisture plays a big part in the movement of tannins. When the timber is dry, tannin bleed will rarely take place. However, the application of water-based coatings provides sufficient moisture for the soluble tannins to become mobile and leech out of the wood. Although tannin discolouration is more likely in areas exposed to the worst weather, timber in persistent damp but sheltered locations will also be prone to tannin bleed. Without the right preventative measures, tannin bleed is always a risk.

Secondly, because of the cell structure of timber, sawn-ends and end grains are the most vulnerable to tannin bleed. End grains are prone to sucking up water as the timber is damp, and will release the water as it dries. Without protection, end grains will leak tannins and discolour finished windows and doors.

Finally, while tannin bleed can occur in any wood species, this is a more common phenomenon in tannin rich hardwoods such as Idigbo and Oak. However, it can occur in less tannin rich timbers such as Sapele and Eucalyptus Grandis. By paying attention to the wood type you can ensure that you have the best possible protection.

While tannin bleed in hardwoods such as Idigbo and Oak will be present in any given colour of finish, the bleed will be more obvious on white or lighter finishes. This all seems very problematic, but the solution is actually very simple.

How to prevent tannins from ruining finished coatings?

First, ensure that the timber is dried sufficiently prior to use. We recommend a moisture content of between 14% and 16%. Not only will this make the wood easier to work with, but it will also minimize the amount of moisture that is released by the timber, minimizing the risk that tannins will leak out. You should also think about the amount of water and damp conditions that will affect the finished product and provide sufficient protection.

Second, end grains and cut ends should be sufficiently protected with Hydrolux End Grain sealer. This will give additional protection to parts of the timber that are susceptible to bleeding tannins.

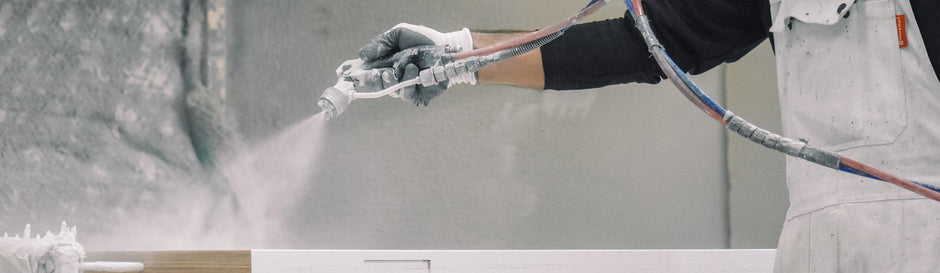

Third, we recommend using Anker Stuy Iso Primer. While some timber types are more likely to bleed tannins, it is a possibility with all wood types. Our Hydrolux Iso Primer is a water-based industrial primer for all interior and exterior timbers based on Tri-Cryl® technology. This primer has excellent isolating properties which help minimize tannin bleed and discolouration in the paint finish, creating an isolating barrier resulting in a clean finish every time.

By following these simple steps you can protect yourself against wasting money on costly repair or replacement jobs and have confidence in a long-lasting finished product of superior quality. Improve your products today and protect yourself against tannin bleed with Anker Stuy’s Iso Primer.